| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Go-Gold |

| Model Number : | KG-80110GM310 |

| Certification : | ISO |

| Price : | Negotiation |

| Payment Terms : | L/C, T/T, Paypal |

| Supply Ability : | 10000pcs-30days |

| Delivery Time : | 7days for samples |

Lead Time

| Quantity(pcs) | 1-1000 | 1001-10000 | >10000 |

| Leam Time(days) | 15 | 30 | To be negotiation |

Performance specification

| Rated Voltage | 310V | Rated Current | 1.7A |

| Rated Speed | 6000RPM | No-load Cureent | 0.4A |

Essential Detials

Warranty: 3Years

Place of Origin: Guangdong, China

Brand Name: Go-Gold

Model Number: KG-80110GM310

Usage: Medical Equipment

Type: Gear Motor

Rated Torque: 0.7N.m

No-load Speed: 8000RPM

No-load Current: 30mA

Product Name: Door Lock Motor Gear Motor

Certification: ISO

Rated Voltage: 310V

Keywords: Medical Equipment Motor

Noise: Low

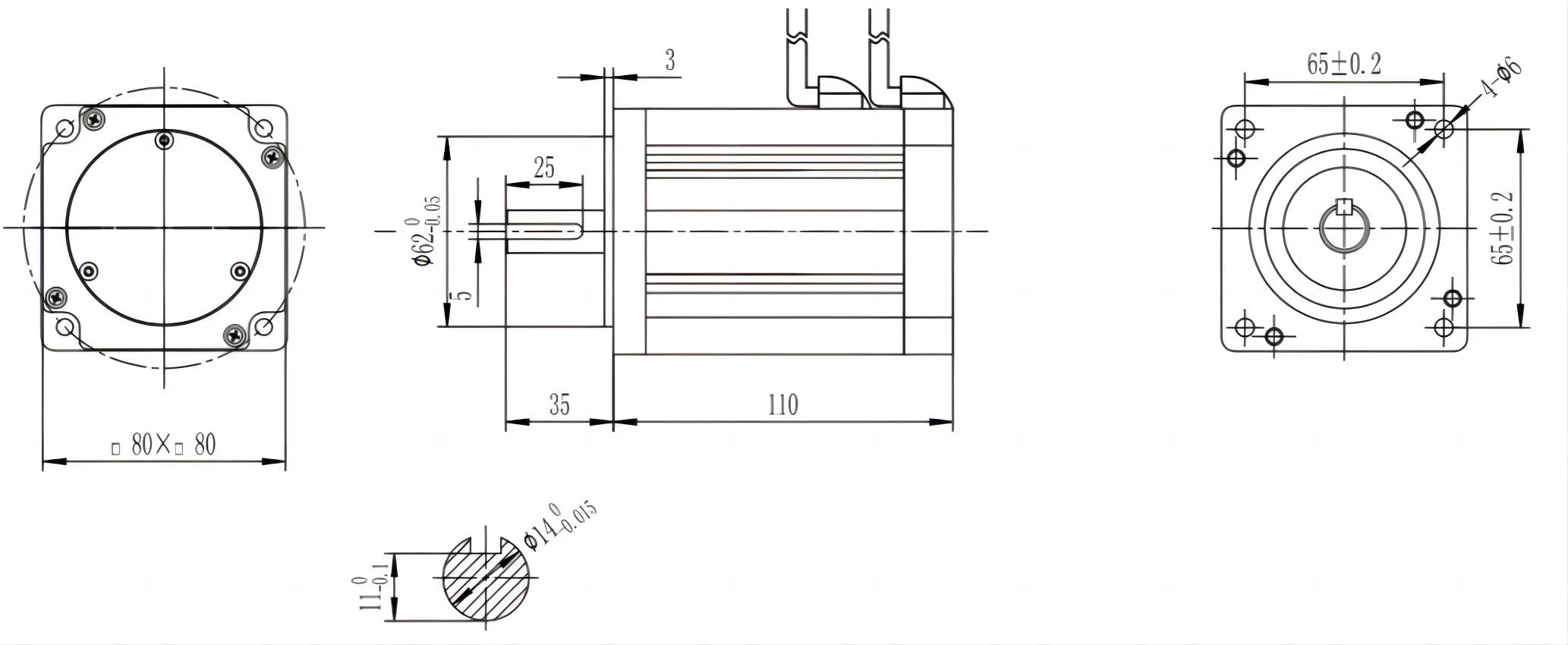

Dimensions

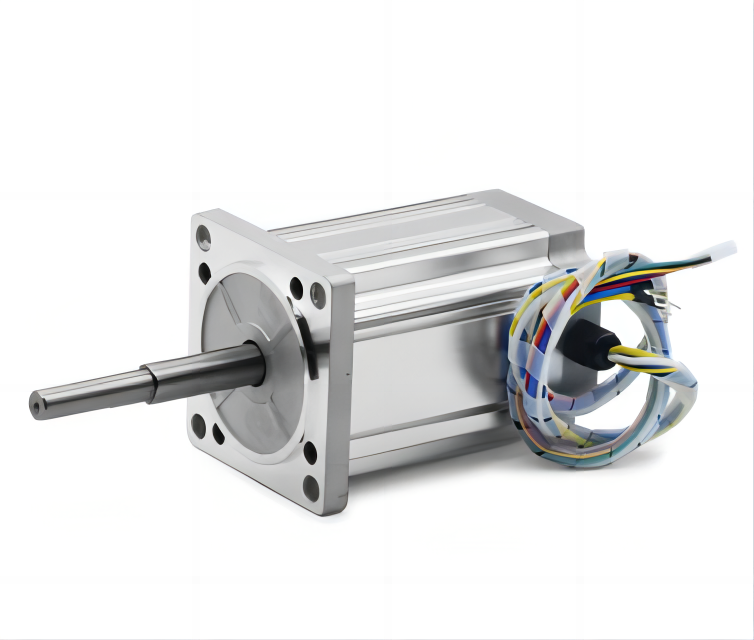

Motor Picture

About Gear Motor

Gear Motor is an independent component consisting of gear transmission, worm transmission, and gear-worm transmission enclosed in a rigid shell. It is often used as a reduction transmission device between the prime mover and the working machine. Or the actuators play the role of matching speed and transmitting torque.

Gear Motors are generally used for transmission equipment with low speed and high torque. Its basic working principle is: the power of the motor and high-speed operation is passed through the gear with a small number of teeth on the input shaft of the reducer to mesh with the large gear on the output shaft to achieve deceleration. Purpose, an ordinary reducer will also have several pairs of gears with the same principle to achieve the ideal reduction effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.

Features of Gear Motor

The Main Functions of the Gear Motor Include the Following Two Points

1) Decrease the speed and increase the output torque at the same time. The torque output ratio is based on the motor output multiplied by the reduction ratio, but be careful not to exceed the rated torque of the reducer;

2) Deceleration also reduces the inertia of the load, and the reduction in inertia is the square of the reduction ratio.

The Gear Motor is actually a power transmission mechanism that does not generate power by itself. Its function is to use different gear sizes and speed converters to reduce the number of revolutions of the motor to the desired number of revolutions; and obtain greater torque. of institutions. Of course, some people will have doubts. Isn't it enough to just ignore the reducer and adjust the speed of the motor? In fact, it is not the case. The reducer is a mechanism that obtains larger torque when changing the speed. The motor is directly connected to the equipment. When the equipment is running, the load on the motor is very large, which will cause great damage to the motor. However, it is different after a reducer. For example, a reducer with a reduction ratio of 100, when the machine is running The load on the motor is only one percent, thus reducing the loss of the motor. In addition, if the reducer is damaged, you only need to replace the gear, and the cost is much lower than that of the motor. If the motor is damaged, it will undoubtedly lead to the expansion of the accident.

|