| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Go-Gold |

| Model Number : | KG-80110GM310 |

| Certification : | ISO |

| Price : | Negotiation |

| Payment Terms : | L/C, T/T, Paypal |

| Supply Ability : | 10000pcs-30days |

| Delivery Time : | 7days for samples |

Performance specification

| No-load Current | 1.7A | Power | 440W |

| No-load Speed | 8000RPM | No-load Cureent | 0.4A |

Lead Time

| Quantity(pcs) | 1-1000 | 1001-10000 | >10000 |

| Leam Time(days) | 15 | 30 | To be negotiation |

Essential Detials

Warranty: 3Years

Place of Origin: Guangdong, China

Brand Name: Go-Gold

Model Number: KG-80110GM310

Usage: Medical Equipment

Type: Gear Motor

Rated Torque: 0.7N.m

No-load Speed: 8000RPM

No-load Current: 30mA

Product Name: Door Lock Motor Gear Motor

Certification: ISO

Rated Voltage: 310V

Keywords: Medical Equipment Motor

Noise: Low

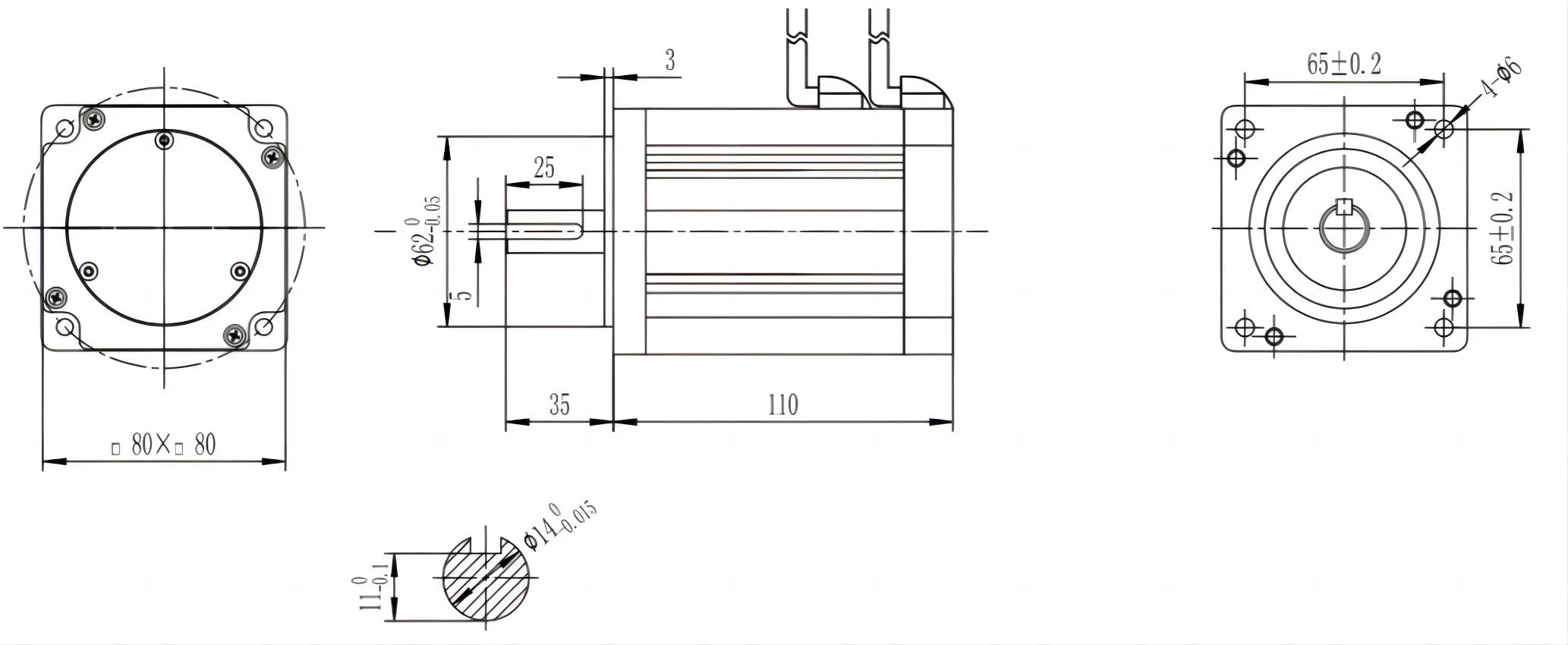

Dimensions

Motor Picture

Working Principle and Function of Gear Motor

Gear Motor refers to the integration of reducer and motor, also known as gear reduction motor or gear motor. It is basically supplied in complete sets after being assembled by the reducer manufacturer.

Its working principle is to transfer the power of the motor to the motor through the gear reducer, thereby greatly reducing the speed and thereby increasing the output torque of the gearbox reduction motor to meet the needs of mechanical equipment. This kind of power transmission equipment has a core "power-increasing deceleration" function that cannot be ignored. It uses gear transmission at all levels to achieve the purpose of deceleration. The reducer is composed of gear pairs at all levels.

The most commonly used gear motors are: coaxial helical gearbox reduction motor; parallel axis - helical gearbox reduction motor; bevel gear - helical gearbox reduction motor; bevel gear worm gearbox reduction motor.

The Gear Motor Mainly has the Following Three Functions

1. Deceleration: The speed of the motor reaches the required speed through the deceleration gearbox, which is often referred to as the output speed.

2. Increase torque: With the same power, the slower the output speed, the greater the torque, and vice versa.

3. Change the transmission direction: The gearbox reduction motor can transmit torque 90 degrees vertically.

The Role of Bearings in Gear Motors

Bearings are key components in gearbox motors. Bearings have the

following main functions

|