| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

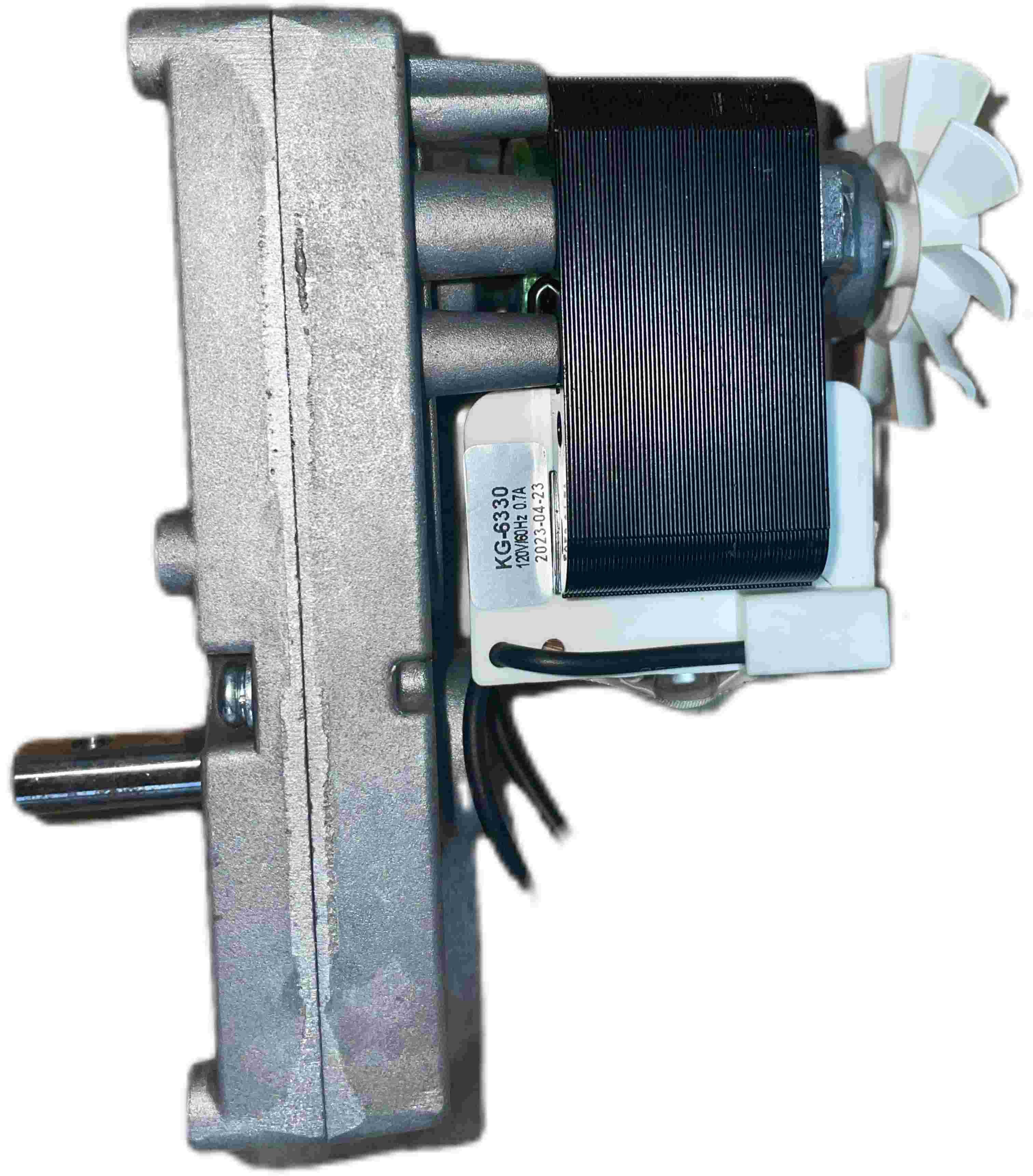

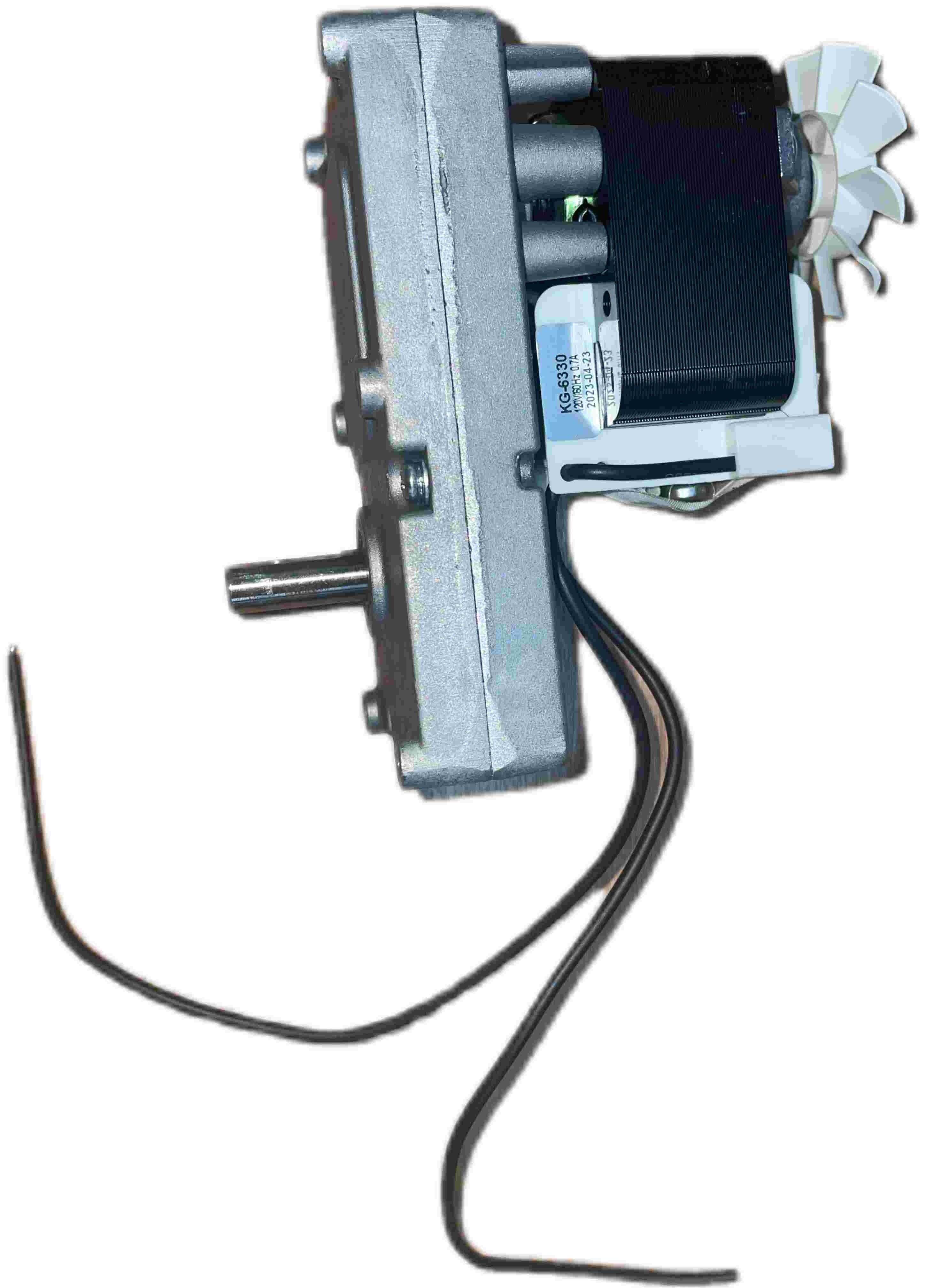

| Brand Name : | Go-Gold |

| Model Number : | KG-GM61C |

| Certification : | ISO |

| Price : | negotiation |

| Payment Terms : | L/C, T/T,paypal |

| Supply Ability : | 10000 pcs-30 days |

| Delivery Time : | 7days for samples |

Product Description

Voltage(V): | 100-240V | Torque(Nm): | 0.5-10N.m |

Input power(W): | 10-100W | Rated speed(RPM): | 3-30RPM |

A gearbox motor structure, characterized in that it includes a motor, a worm, and a gear box. The motor has a bearing chamber and a motor shaft installed on the bearing chamber. The worm is installed on the motor shaft, and the side wall of the gear box is provided with an installation hole and a through groove. The installation hole is connected to the through groove, and the worm can be installed in the gear box through the motor shaft from the through groove through the installation hole, The bearing chamber is installed in the mounting hole.

Definition: Gearbox, also known as gearbox, is a power transmission mechanism that converts the speed of the motor to the required speed of the executing device through the meshing of gears with different numbers of teeth, and can change the torque of the mechanism.

Outer dimension

Application

Internal structure of GEAR MOTOR

GEAR MOTOR is a mechanical transmission device mainly used to

convert the high-speed rotation of a motor into a low-speed and

high grip output. The internal structure of the gearbox is complex,

consisting of multiple gears, bearings, oil seals, and other

components. Let's have a detailed understanding of the internal

structure of the lower gearbox

The main component of a gearbox is the gears, which usually have

multiple gears connected together through gear shafts. There are

many types of gears, including cylindrical gears, bevel gears, worm

gears, etc. Different types of gears have different force surfaces

such as tooth shape, number of teeth, and modulus, so their

applications inside gearboxes are also different.

There are also bearings inside the gear motor, which are mainly

used to support the gear shaft and reduce friction. There are also

many types of bearings, including rolling bearings, sliding

bearings, etc. The advantages of rolling bearings are low friction

and long service life, but lubrication is required, while sliding

bearings do not require lubrication, but high friction and short

service life:

There are also oil seals inside the gear motor, which are used to

prevent lubricant leakage. There are also many types of oil seals,

including single lip oil seals, double lip oil seals, etc. The

selection of oil seals should be determined based on factors such

as the type of lubricating oil inside the gearbox, temperature,

pressure, etc.

In addition to the above components, there are also other shaft

power components inside the gear, such as bearing seats, bearing

covers, bearing sleeves, etc. Although these components are not the

core components inside the gear motor, their quality and accuracy

can also affect the performance and lifespan of the gear motor.

|