| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Go-Gold |

| Model Number : | KG-1214DC12 |

| Certification : | ISO |

| Price : | Negotiation |

| Payment Terms : | L/C, T/T, Paypal |

| Delivery Time : | 7days for samples |

Motor Details

Warranty: 3Years

Place of Origin: Guangdong, China

Brand Name: Go-Gold

Model Number: KG-1214DC12

Usage: Electric Curtains

Current(A): 0.35A

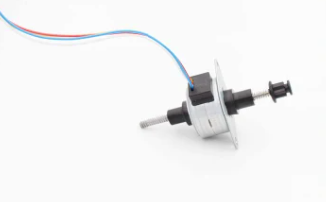

Product Name: Electric Curtains Motor DC Motor

Motor type: DC Motor

Certification: ISO

Rated Voltage: 12V/ Customized

Keywords: Electric Curtains Motor

Noise: Low

Lead Time

| Quantity(pcs) | 1-1000 | 1001-10000 | >10000 |

| Lead Time(days) | 15 | 30 | To be negotiation |

Performance Specifications

| Rated Voltage | DC12V | Weight | 50g |

| Max Efficiency Current | 0.35A | Insulation Class | E |

Dimension

Motor Picture

Motor Application

Composition and Structure of DC Motor

The structure of DC motor should be composed of two parts: stator

and rotor. The stationary part of DC motor is called stator. Its

main function is to generate magnetic field. It is composed of

base, main magnetic pole, commutation pole, end cover, bearing and

brush device. The rotating part is called rotor. Its main function

is to generate electromagnetic torque and induced electromotive

force. It is the hub of energy conversion of DC motor, so it is

usually called armature. It is composed of rotating shaft, armature

core, armature winding, commutator and fan.

Stator

(1) Main magnetic pole

The function of main magnetic pole is to generate air gap magnetic

field. Main magnetic pole is composed of main magnetic pole core

and excitation winding. The core is generally made of 0.5mm~1.5mm

thick silicon steel sheet punching and riveting. It is divided into

pole body and pole shoe. The part with excitation winding on the

top is called pole body, and the part with widening on the bottom

is called pole shoe. Pole shoe is wider than pole body, which can

adjust the distribution of magnetic field in air gap and facilitate

the fixing of excitation winding. The excitation winding is wound

with insulated copper wire and is mounted on the main pole core.

The entire main pole is fixed to the base with screws.

(2) Commutation pole

The function of the commutation pole is to improve commutation and

reduce the commutation sparks that may be generated between the

brush and the commutator when the motor is running. It is generally

installed between two adjacent main poles and consists of a

commutation pole core and a commutation pole winding. The

commutation pole winding is wound with insulated wire and is

mounted on the commutation pole core. The number of commutation

poles is equal to the main poles.

(3) Base

The outer shell of the motor stator is called the base. The base

has two functions:

One is to fix the main poles, commutation poles and end covers, and

to support and fix the entire motor;

The other is that the base itself is also part of the magnetic

circuit, which constitutes the magnetic path between the poles. The

part through which the magnetic flux passes is called the yoke. In

order to ensure that the base has sufficient mechanical strength

and good magnetic conductivity, it is generally a cast steel part

or welded from steel plates.

(4) Brush device

The brush device is used to introduce or extract DC voltage and DC

current. The brush device consists of a brush, a brush holder, a

brush rod and a brush rod seat. The brush is placed in the brush

holder and compressed by a spring to ensure good sliding contact

between the brush and the commutator. The brush holder is fixed to

the brush rod, and the brush rod is installed on the annular brush

rod seat. They must be insulated from each other. The brush rod

seat is installed on the end cover or the inner cover of the

bearing. The circumferential position can be adjusted and fixed

after adjustment.

Rotor

(1) Armature core

The armature core is the main part of the main magnetic circuit and

is also used to embed the armature winding. Generally, the armature

core is made of 0.5mm thick silicon steel sheets punched and

stacked to reduce the eddy current loss and hysteresis loss

generated in the armature core when the motor is running. The

stacked core is fixed on the shaft or rotor bracket. The outer

circle of the core is opened with armature slots, and the armature

winding is embedded in the slots.

(2) Armature winding

The function of the armature winding is to generate electromagnetic

torque and induced electromotive force. It is a key component for

DC motors to convert energy, so it is called armature. It is

composed of many coils (hereinafter referred to as components)

connected according to a certain rule. The coils are wound with

high-strength enameled wire or glass-wrapped flat copper wire. The

coil edges of different coils are divided into upper and lower

layers and embedded in the armature slots. The coils and the core

and the upper and lower layers of coil edges must be properly

insulated. To prevent the centrifugal force from throwing the coil

edges out of the slot, the slot is fixed with a slot wedge. The end

of the coil extending out of the slot is tied with a thermosetting

non-weft glass tape.

(3) Commutator

In a DC motor, the commutator is equipped with brushes, which can

convert the external DC power supply into alternating current in

the armature coil, so that the direction of the electromagnetic

torque remains constant; in a DC generator, the commutator is

equipped with brushes, which can convert the alternating

electromotive force induced in the armature coil into DC

electromotive force drawn from the positive and negative brushes.

The commutator is a cylinder composed of many commutator segments,

and the commutator segments are insulated with mica sheets.

(4) Rotating shaft

The rotating shaft supports the rotation of the rotor and needs to

have a certain mechanical strength and rigidity. It is usually made

of round steel.

|