| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Go-Gold |

| Model Number : | KG-1214DC12 |

| Certification : | ISO |

| Price : | Negotiation |

| Payment Terms : | L/C, T/T, Paypal |

| Delivery Time : | 7days for samples |

Lead Time

| Quantity(pcs) | 1-1000 | 1001-10000 | >10000 |

| Lead Time(days) | 15 | 30 | To be negotiation |

Performance Specifications

| Rated Voltage | DC12V | Weight | 50g |

| Max Efficiency Current | 0.35A | Insulation Class | E |

Motor Details

Warranty: 3Years

Place of Origin: Guangdong, China

Brand Name: Go-Gold

Model Number: KG-1214DC12

Usage: Electric Curtains

Current(A): 0.35A

Product Name: Electric Curtains Motor DC Motor

Motor type: DC Motor

Certification: ISO

Rated Voltage: 12V/ Customized

Keywords: Electric Curtains Motor

Noise: Low

Dimension

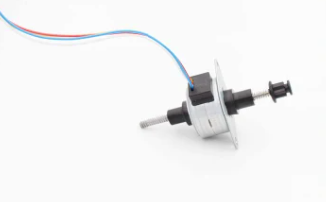

Motor Picture

Motor Application

Definition of DC Motor

DC motor refers to a rotating motor that can convert DC electric

energy into mechanical energy (DC motor) or mechanical energy into

DC electric energy (DC generator). It is a motor that can realize

the mutual conversion of DC electric energy and mechanical energy.

When it operates as a motor, it is a DC motor, converting electric

energy into mechanical energy; when it operates as a generator, it

is a DC generator, converting mechanical energy into electric

energy.

Comparison With AC Motors

The advantage of DC motors is that they are relatively simple to

control speed. You only need to control the voltage to control the

speed. However, this type of motor is not suitable for operation in

high temperature, flammable environments, etc. Many direct-acting

motors require carbon brushes as components of the current

converter (DC brushed motors), so it is necessary to regularly

clean the dirt generated by the friction of the carbon brushes. DC

motors without carbon brushes are called DC brushless motors.

Compared with brushless motors, brushless motors are more

energy-saving and quieter because there is no friction between the

carbon brushes and the shaft. They are more difficult to make and

more expensive.

AC motors can operate in high temperature, flammable environments, etc., and there is no need to regularly clean the dirt on the carbon brushes, but it is more difficult to control the speed because controlling the speed of AC motors requires controlling the frequency of the AC power (or using induction motors, increasing internal resistance to reduce the motor speed at the same AC power frequency). Controlling its voltage will only affect the torque of the motor. The voltage of general industrial DC motors is AC 110V (125V) and AC 220V.

Brushed DC Motors

Brushed DC motors use an internal commutator (commutator), stator

magnets (permanent magnets or electromagnets), and rotating

electromagnets to generate torque from a DC power source.

The benefits of brushed DC motors are low initial cost, high reliability, and a simple way to control the speed of the motor. The disadvantages are high maintenance costs and a low life cycle under intensive use. Maintenance includes periodic replacement of the conductive carbon brushes and springs on the commutator, and the need to clean or replace the commutator. These devices are necessary to transmit external power to the motor.

Carbon brushes are generally made of carbon or graphite, and copper powder is sometimes added to increase conductivity. With use, the soft carbon brush material wears to conform to the radius of the commutator and will continue to wear. The brush holder has springs to maintain pressure on the brush as it shortens. If the brushes carry more than an amp or two of current, there are flying wires placed in the brushes and connected to the motor terminals. Very low-power motors use sliding contacts on the metal brush holder to conduct the current to the brushes, or contact springs press against the ends of the brushes. In very low power, short life motors (such as those in toys), folded metal strips in contact with the commutator are used as brushes.

|